KROFTA ENGINEERING LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KROFTA ENGINEERING LTD.

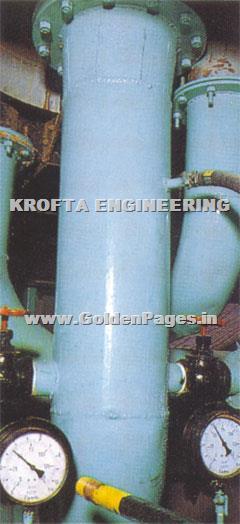

Wet Scrubbing Systems

Wet Scrubbing Systems is the removal of gaseous or particulate contaminants from a gas stream using a liquid. The scrubbing liquid is usually water or an aqueous solution.

Acids or alkalis are often used to control the pH to the optimum level for absorption. Oxidising agents such as hydrogen peroxide or hypochlorite can be used to react with the contaminant.

Venturi Scrubbers:

Venturi scrubbers are an effective means of removing sub micron particulates. The contaminated gas is accelerated in the converging section before entering the throat (see left). Scrubbing liquor enters around the top of the converging section and completely flushes the wall. In addition, liquor enters through a spray to fill the throat with droplets.

In the venturi throat, the high velocity gas atomises the liquid droplets which trap the solid particles. The scrubbed gas and liquid droplets leave the venturi throat and pass through the diverging section where further agglomeration takes place to produce larger droplets. The liquor droplets are then separated from the gas stream in a cyclonic entrainment separator.

To ensure high scrubbing efficiencies, even with varying gas flows, the throat can be made adjustable, thus maintaining the required scrubber pressure drop, even at reduced throughputs.

The liquor from the separator is recycled via pumps to the venturi scrubber with a small bleed being discharged to control the build up of solids in the circulating liquor.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.